Besides this project, I had already some experiences this semester to explore the possibilities in the field of music machines. For the final presentation in “ESC medien kunst labor” I presented a plastic “Hackbrett” played by one DC Motor. The generated sound was then recorded and processed in real-time via PureData.

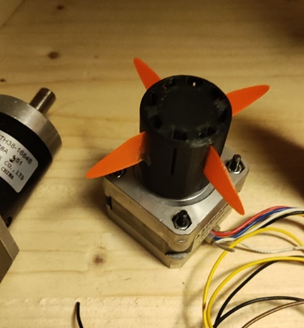

The interaction with the instrument occurred using a 3D-printed cylinder mounted on the motor. The different slices on the sides were positioned at equal distances to insert guitar picks. The goal was to emulate an analog score capable to play different patterns according to the distances between the picks.

Even though this process seemed to be satisfying, due to the distance to the strings and the movement of the motor, it was difficult to manage a continuous pattern or intensity. For this reason, after discussing the idea with professor Ritsch, we obtain for the solenoids to play the instrument.

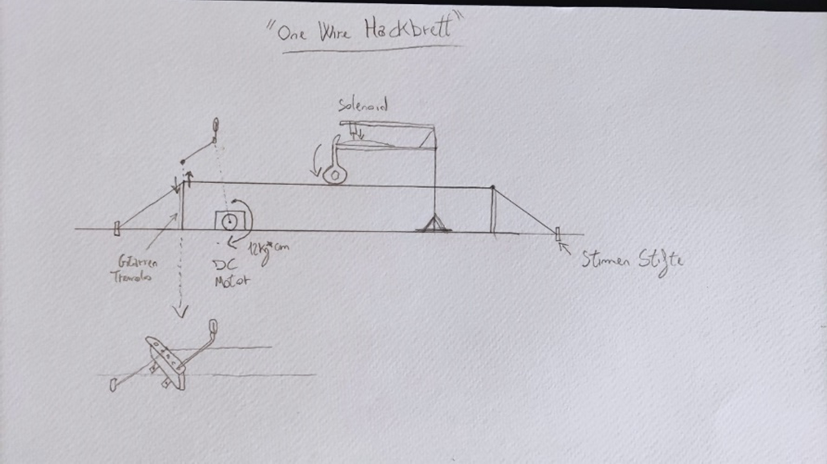

Next, I designed a prototype with only one string and a hammer with additionally a lever to be able to change the pitch of the string and obtain further nuances in the timbre. The idea is to build a simplified version of the final machine to analyze the possibilities, limitations, and different technical challenges of this instrument. Although the construction is very rudimentary, through this process, I would learn useful information to better set the technical components and then decide how to play it from the artistic point of view.

The system works mechanically through two core elements: the hammer that reproduces the percussive sounds (solenoid) and the lever (servo motor) that contributes to shifting the pitch. With the first one I reproduce different rhythmical patterns that can be modified in real-time by means of pre-programmed sequences and with the lever, like for an electric guitar, I produce timbral variations in the frequency domain.

The image below represents the first sketch of the prototype:

Regarding the electronic part of the development process, I took inspiration from a project made by Professor Ritsch during my second semester at IEM, the “Coeus”:

“previous “autodrummer” and later percussion robot aka “Doppelschlagwerke”, now robot musician is targeted building robotic instrument player with microcontrollers in the IoT generation, which are designed to play all kind of drums, gongs, pipes, strings … or other similar new created instruments or sounding objects very accurate and dynamically as quickly as possible or slow with optional dampers – making up a automata as instrument player, a robotic musician controllable over a network via OSC (Open Sound Control Syntax).”[1]

Analyzing his concept, I reorganized the electronic parts I needed to design a robot that would meet my technical requirements. Here the list of electronic components that I used:

- One Solenoid push-pull;

- DC Motor[2];

- DC/DC Stepdown converter[3];

- ESP32-DevKit-Lipo with battery over WIFI;

- 24V external power supply

[1] https://git.iem.at/ritsch/coeus/-/tree/master/

[2] Servomotor – CDN-Reichelt.de (no date). Available at: https://cdn-reichelt.de/documents/datenblatt/A300/COM-MOTOR02-DATENBLATT.pdf (Accessed: January 26, 2023).

[3] DC-DC Stepdown Modul LM2596S (no date) 3DJake Österreich. Available at: https://www.3djake.at/bigtreetech/dc-dc-stepdown-modul?gclid=CjwKCAiA5sieBhBnEiwAR9oh2v_YBqQJkIaTMVZ3Pr1sqGGeMtlf2k7Fa4m72bm-v9hGE5iRAfGhzxoCTWoQAvD_BwE (Accessed: January 26, 2023).